FAQ

In addition to our own stock, it is possible to supply your own material. The residual material is given when the order is delivered. We can dispose of the residual material for a small fee.erial

The costs for milling are determined by a number of factors that differ per design. Such as, the delivery of the design, the complexity of the design, the amount of milling work and the complexity. It is therefore not possible to give an indication in advance, but we trust to be able to offer you a suitable and competitive offer.

The delivery time depends on the lead time on the product and the complexity of your design. Consider, for example, the type of material and specific operations. Contact us if you have a more complex project or if you work within a schedule.

Sheet material in various types of wood, MDF, plywood, acrylic and EPS (polystyrene). Soft metals are possible after consultation. Our own stock consists of various plates in different thicknesses and dimensions. Depending on the design, we will coordinate with you what the best material for your design is. If we don’t have your material in stock, that’s no problem. Due to good cooperation with our suppliers, most can be received within 1 working day. If you have any questions, please contact us. The details can be found on the contact page.

Much is possible, much more than often thought. For example, the possibilities are not limited to the processing of sheet material, but manufacture in 3D is also possible. Whether that is a single piece or series production. Some examples are; prototypes, molds and semi-finished products. Decorative panels to be used for doors, fencing, partitions, room dividers, acoustic panels, wall decoration and lighting. Get in contact. The details can be found on the contact page. We are happy to inform you about the possibilities, specific details and costs for your design.

Residual material from the material supplied by us will be removed for you, unless indicated otherwise. When using the material supplied by you, the residual material is included with the order. We can dispose of it for you. A small fee is charged for this.

In addition to milling services, we offer consultation for the various components in the process from sketch to production model. Through the development and production of our own products, we are specialized in the various steps within the process from idea to a physical product. Under services you can read what the options are. Or you can contact us.

We are happy to receive technical drawings in the following formats, .ai, .dxf, .dwg.

When requesting a quote, you can include it immediately.

Do you have any questions? Then we would like to hear it. That is easy via our contact page.

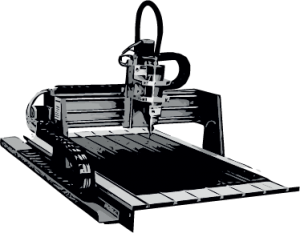

The process from idea to production model and manufacturing has a number of steps: idea, design, digitization, programming control milling machine, production. Contact us so that we can inform you about the various options, specific details and costs. You will find our details on the contact page. When requesting a quote, you can include it immediately.

Do you have any questions? Then we would like to hear it. That is easy via our contact page.

Because the manufacture of a single piece is also very possible, our services are accessible to everyone. You do not have to be a professional with a minimum order quantity. Check our contact page for our details. We are happy to think along with you about what the options might be for you.

Do you have any questions? Then we would like to hear it. That is easy via our contact page.